Our DownTown Marketplace - Storefront Apartment Display Windows

We certainly started out with grand ideas for the "Downtown Marketplace", as we call it, and the idea of a small town center as a focus for the Barkyard railroad. The idea was to slowly populate downtown with buildings using the concrete casting technique coupled with a concrete block for strength. There are some drawbacks to using this method, but the speed of production is the key to why we're using this approach.

The first casting was the grand experiment, which is to say it had flaws. Flaws we had to work around. But work around them we did. We modelled these buildings after the well known storefront apartment series styrene model kits available in many scales... Except large scale. So here we are, making our own version. We'd like to say verions, plural, but one thing at a time.

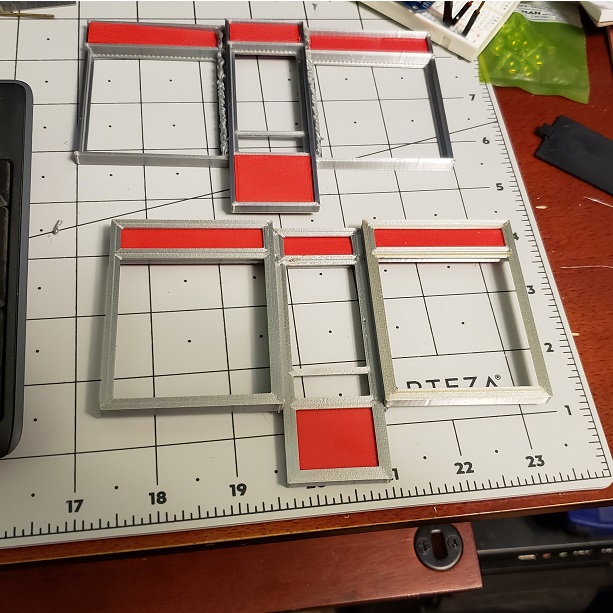

The next stumbling block, if you can call it that, is all the raw, rough openings in the casting where windows belong. And designing the window frames certainly takes some time. I'd been mucking around with a multi-piece window design for quite a while, trying to capture the spirit of commercially available designs, but the overhang restrictions placed on 3D printed parts make it nearly impossible to recreate them.

I work around those restrictions using supports for the void left beneath the upper sash. Once the supports are removed, translucent window panes, or lites, are placed behind the frames as a view block. I experimented with adding dimension to the translucent panes, also 3D printed, simulating a venetian blind pattern. It's visisble, albeit subtle. The most striking viewblock is a piece of opaque black ABS.

Now that we've got the windows covered, time for the display case window frames and entry. After all, this is a storefront apartment building! Again the design difficulty revolves around avoiding supports, but it means printing multiple pieces that will need joined together as a single unit. So how do we join those pieces in a rugged fashion?

People rave online about using a "PLA pen", supposedly capable of "plastic welding" parts together. It's a thermal pen that turns PLA or other types of 3D printing filament into a molten bead of plastic. So I bought one and tried it... Let's just say it's not the end all, do all means of fastening 3D printed plastic to itself. It works well enough, but long term it won't be as rugged or reliable as we need.

Another choice is super glue, but I've NEVER had success using it to stick ANYTHING together, other than my fingers! I'm looking for something akin to liquid styrene cement, but for other plastics. I know plastruct has different formulations for different types of plastic, but I'm tired of paying outrageous prices for miniscule amounts. Long story short, acetone (dimethyl ketone) does a good job bonding ABS, and chloroform (trichloromethane) works wonders for PLA!

I should raise safety concerns about using these products and the harm they can cause if carelessly used or abused. The same concerns one would express about using styrene plastic model cement would apply here. I believe the key ingredients are toluene and MEK (methyl ethyl ketone). Look at it this way, anything strong enough to melt plastic probably isn't good for you or your skin either. Fun fact, anyone that remembers Avon "Skin So Soft" should know it contained toluene to soften skin...

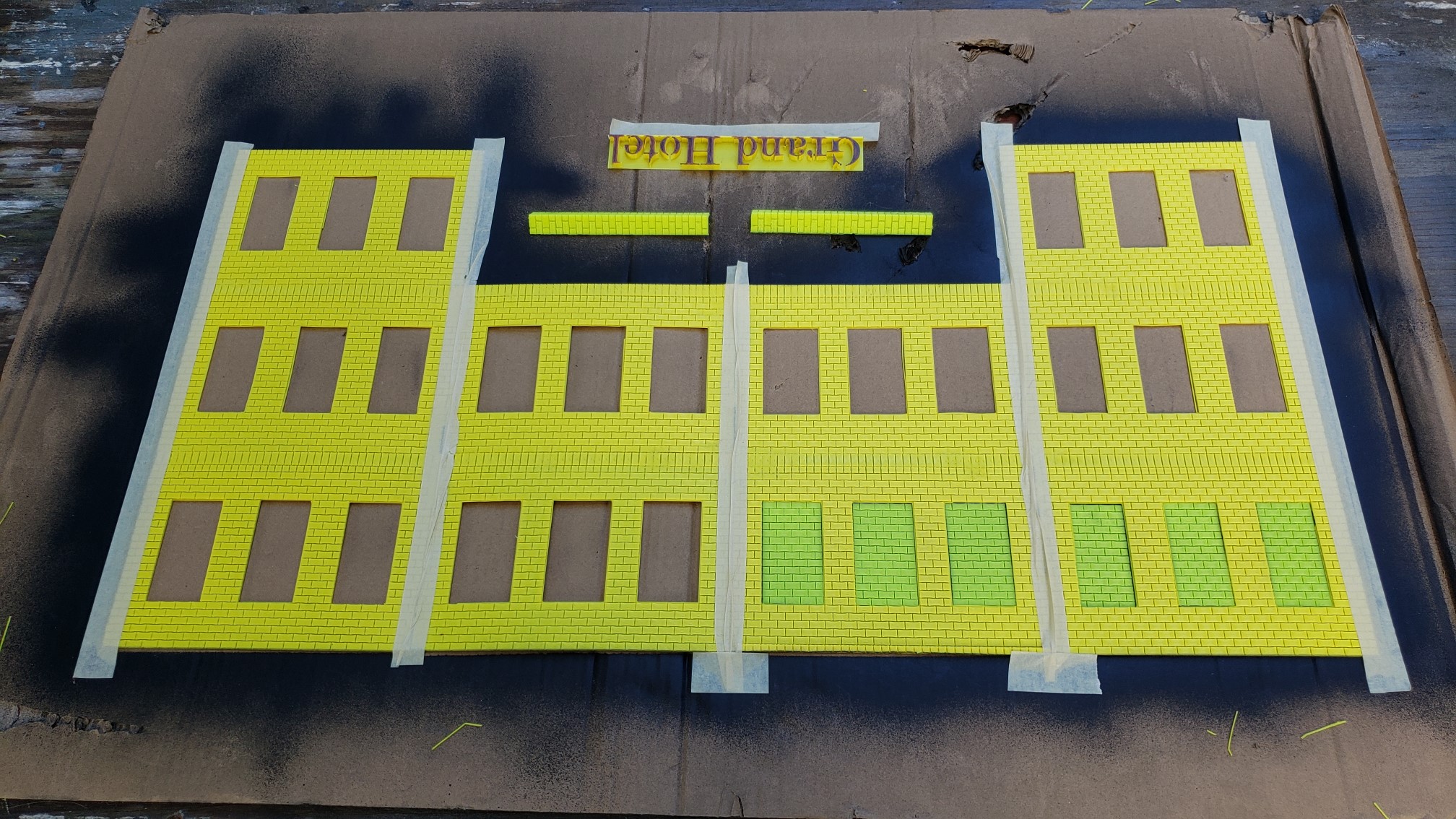

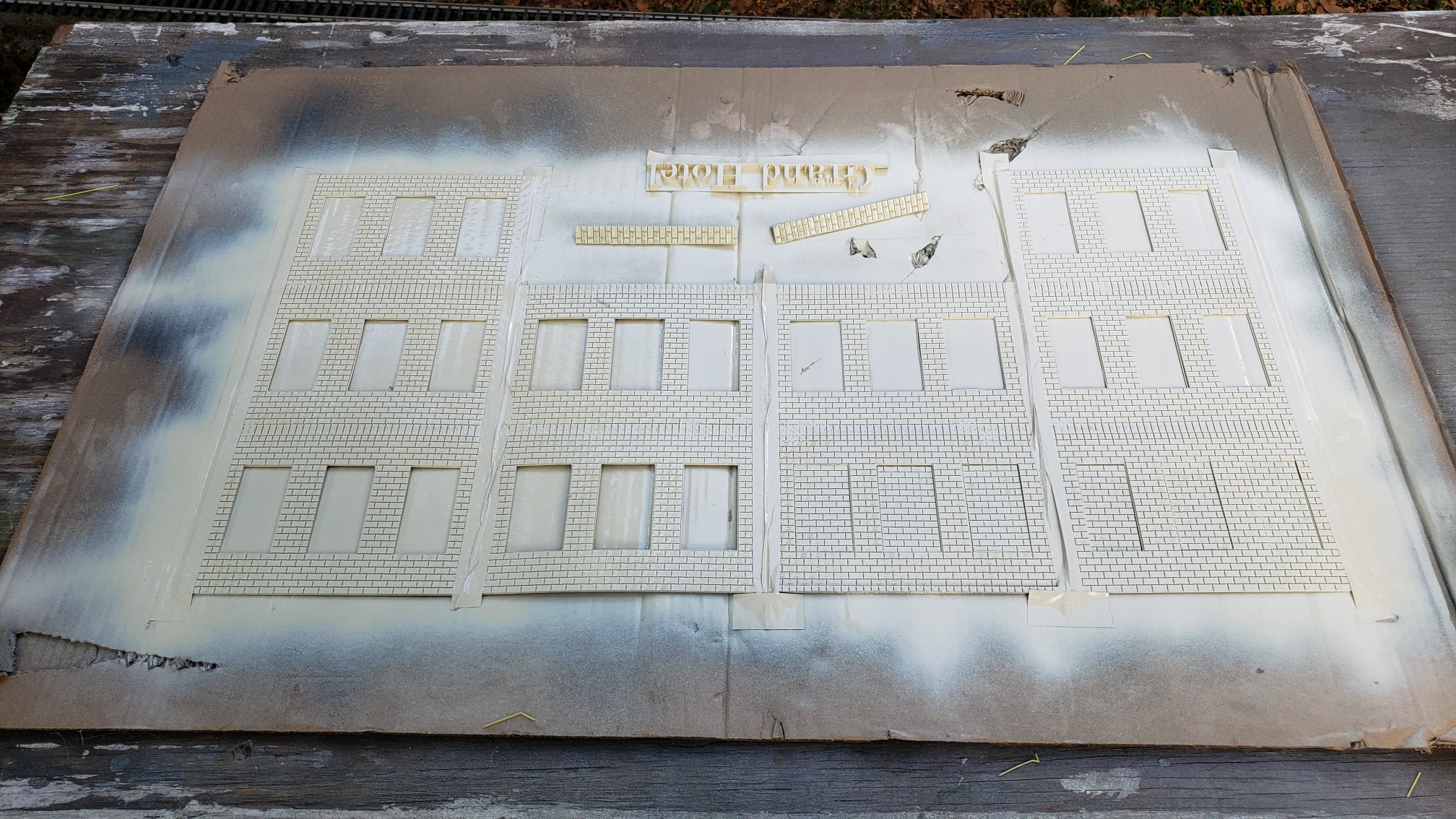

So why does all this matter? Let's add another dimension to the story. While all the software development was shaping the lighting controller, we were designing 3D printed "skins" for the downtown buildings. The original storefront apartment buildings already had their cast faces, but everything else was just bare concrete blocks. The first step was to create a model of those face castings electronically. From there, it becomes a matter of how to assemble and bond the various sections into walls, and those walls into buildings.

The passage of time has not been kind to the Downtown Marketplace. Like the Barkyard itself, it's had many incarnations over time. Distracted by other diversions, what was left of downtown fell into ruin. Main street, once brand new, was now crumbling beneath our feet. The 3D printed windows and showcases, ravaged by the harsh sun, had long since fallen out of the storefront apartment castings, now pummulled beneath puppy paws. Main street suffered a similar fate.

Ann made the observation that it looks like a ghost town and we should make it look haunted for Halloween. So that's what we did! The Grand Hotel slowly emerged, taking shape one 5" x 8" section at a time, each taking more than three hours to print. It takes days of printing and more than two of the one kilogram spools of PLA filament just to print the skin for the Grand Hotel. That's nearly four and a half pounds of plastic! The "Corner Drugstore" takes nearly another spool of plastic and it's questionable whether there's enough time left before Halloween to finish it.

It all came together Halloween night. We had lighting controllers configured, installed, and operating in the other buildings while hurriedly finishing the Corner Drugstore as it was getting dark. The Ghost Town display is impressive! We are thoroughly entertained by it and can't wait until next year to add even more of the features we didn't have time to finish this year.

We invite you to enjoy our Halloween Ghost Town on the Barkyard YouTube channel if you're so inclined. We go into much more detail than we could possibly fit on a web

page. Even our Barkyard Blog posts can't capture all the details that videos can.

View Now...

We're able to leverage the work done for the passenger cars, retrofitting the Passenger Car Lighting controller with all the improvements made for the building controllers.

We also added the hardware for the heralds on those cars so equipped, but that's a future installment. Follow the Halloween Ghost Town build in more detail on our Barkyard

Blog!

See More...

We leveraged the work done for the passenger cars, retrofitting the Passenger Car Lighting controller with all the improvements made for the building controllers. We

also added the hardware for the heralds on those cars so equipped, but let feature creep interfere with adding the Christmas light effect in time for Christmas. A day

late... as they say. The effect was "perfected" on Christmas day!

See More...