Taking A "Shortcut" To Our Grand Hotel

What started out as a desire to upgrade the woefully lacking downtown marketplace and its ever diminishing buildings turned into a major production for Halloween 2021. It's difficult to design a 3D printed casting mold as multiple pieces that need assembled into one continuous casting mold. Still working on honing our design, drafting, and 3D printing skills, we needed a way to quickly turn around the downtown marketplace. Enter the idea of a "skin"! Too thin for a "snap fit" approach, those pieces will need glued together.

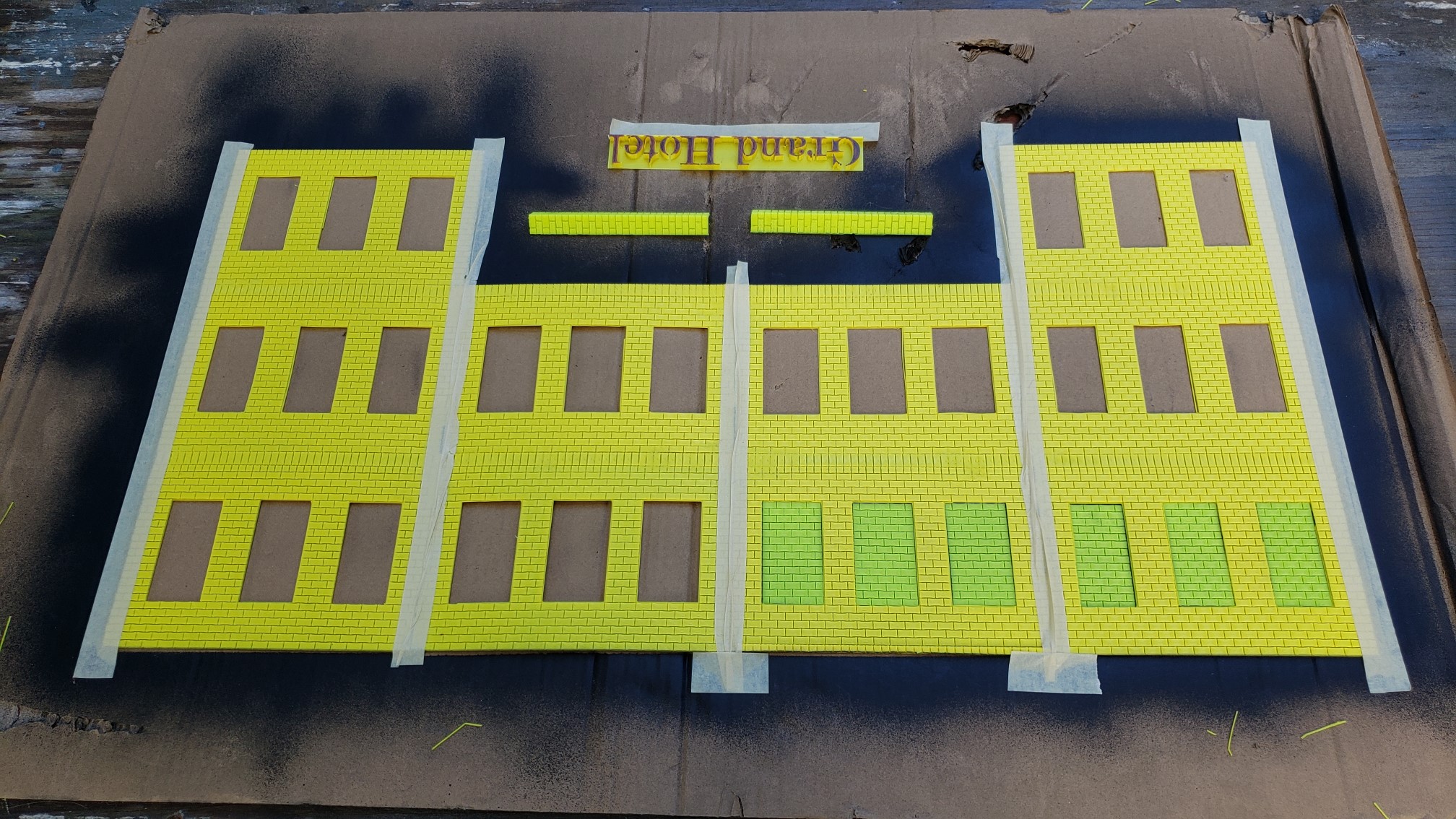

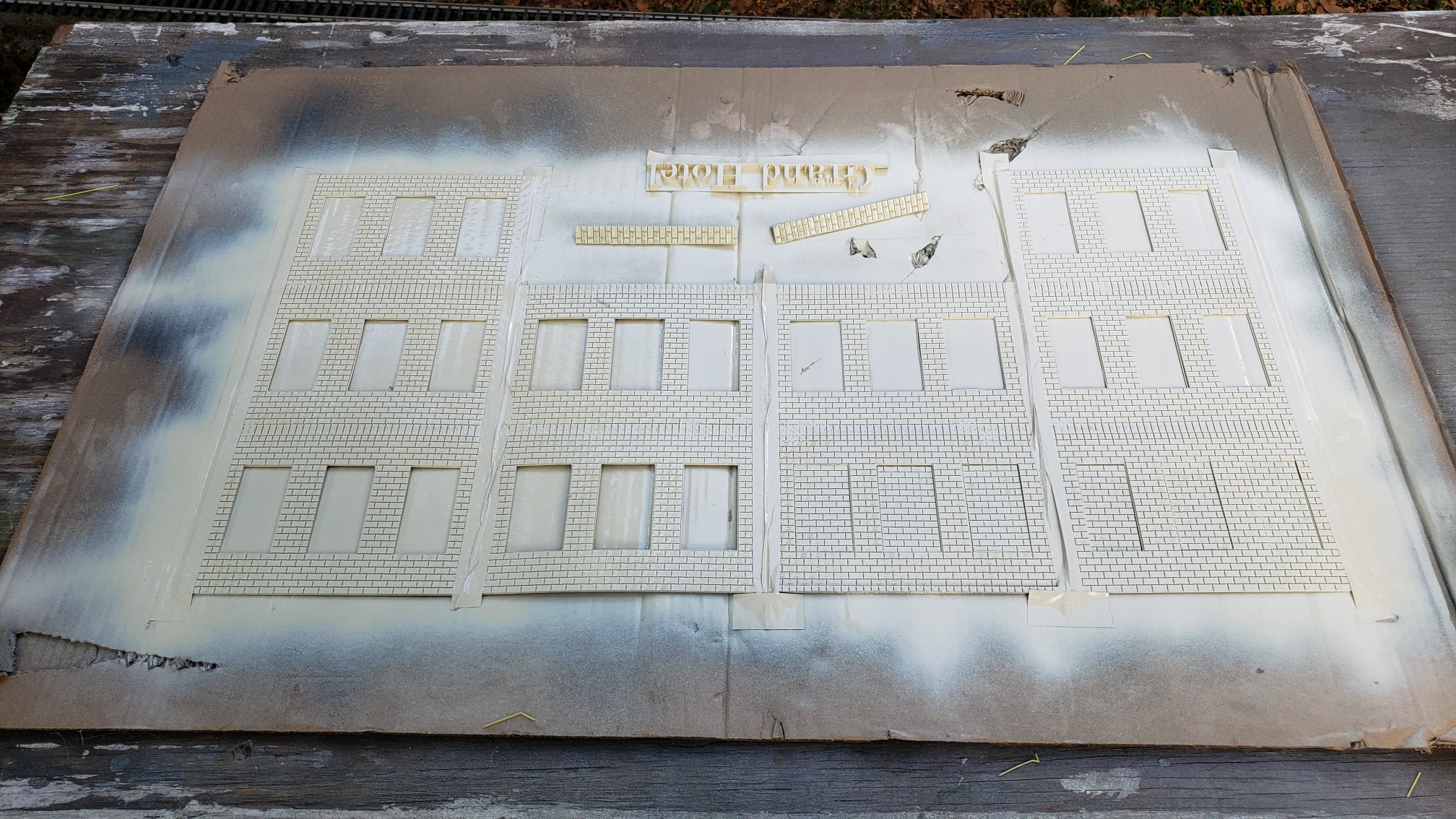

The Grand Hotel skin design centers around standard sized wall panels, 5" x 8", and cemented together like a butt weld. Pillars are used as joint strips to make up the gap between them and strengthen the wall overll, like building a styrene model for a smaller scale indoor layout. It took over three hours to print each 5" x 8" panel and days just to print all the pieces we needed. It consumed more than two spools of PLA filament, that's nearly five pounds of plastic!

The front and rear walls were assembled first, as individual units, 15" tall and 32" long, cementing the panels and joint strips togther. The two outside end walls were easy with just three solid panel to cement together, 15" x 8". Easier still were the inside tower ends walls, a single 5" x 8" panel! Once the four walls were complete, corner pillars joined them into a single skin that fit like a glove, sliding down over the four conrete blocks that comprise its core.

We used concrete blocks as the core support to give substance to the buildings, wrapped with plastic skins to hide those ugly blocks. We already know that plastic is not going to hold up to the dogs, let alone the elements. The blocks are able to withstand an impact and remain in place. Our original castings based on a simple brick pattern sheet, with foam blocks strategically pinned to the pattern sheet to form openings for doors and windows. The castings are roughly ¼" thick and also required concrete blocks to provide support. Mortar was used to attach the castings to the blocks like a veneer.

And while we're much closer to actually casting the walls of the Grand Hotel now, it's still not a reality yet. To design the casting molds requires thinking in reverse. Where a feature on the skin recedes, like the mortar joint lines between the bricks, it must protrude from the mold to create the crevices that make the illusion of mortar joint lines.

Thinking of it another way, while the bricks must protrude from the skin to give the illusion of mortar lines, they must recede into the mold to protrude from the casting. Any protrusions must provide "draft", or an angle vs. an abrupt sharp edge, to allow for easy removal of the casting from the mold. A "mold release" agent is required as well to help prevent the casting from adhering to the mold. This can be cooking oil spray, like PAM, or even WD40 applied to the mold before casting.

The 3D printed casting mold pieces remain the same 5" x 8" form factor, to be plastic cemented together to form a mold for an entire wall, similar to how the skin was assembled. But unlike the original casting method where openings were pinned in place, the 3D printed pieces are much thicker than the thin pattern sheets. That's the last piece of the puzzle to be worked out. Where those openings were created using blocks on insulation foam, they now must be 3D printed and somehow attached to the rest of the wall mold.

We'd like to avoid having to permanently cement them in place since pinning isn't an option because of the thickness of the printed sheets. Thinking about it a bit more, maybe we could use those same foam blocks and hot melt glue them in place. Not sure if the glue will melt the foam or not. One way to find out! If it doesn't work out, maybe just hot melt glue 3D printed blocks in place with the idea of being temporarily attached. If our experience with hot melt glue not wanting to stick to the 3D printed lithophane frame is any indication, there should be no problem using that approach.

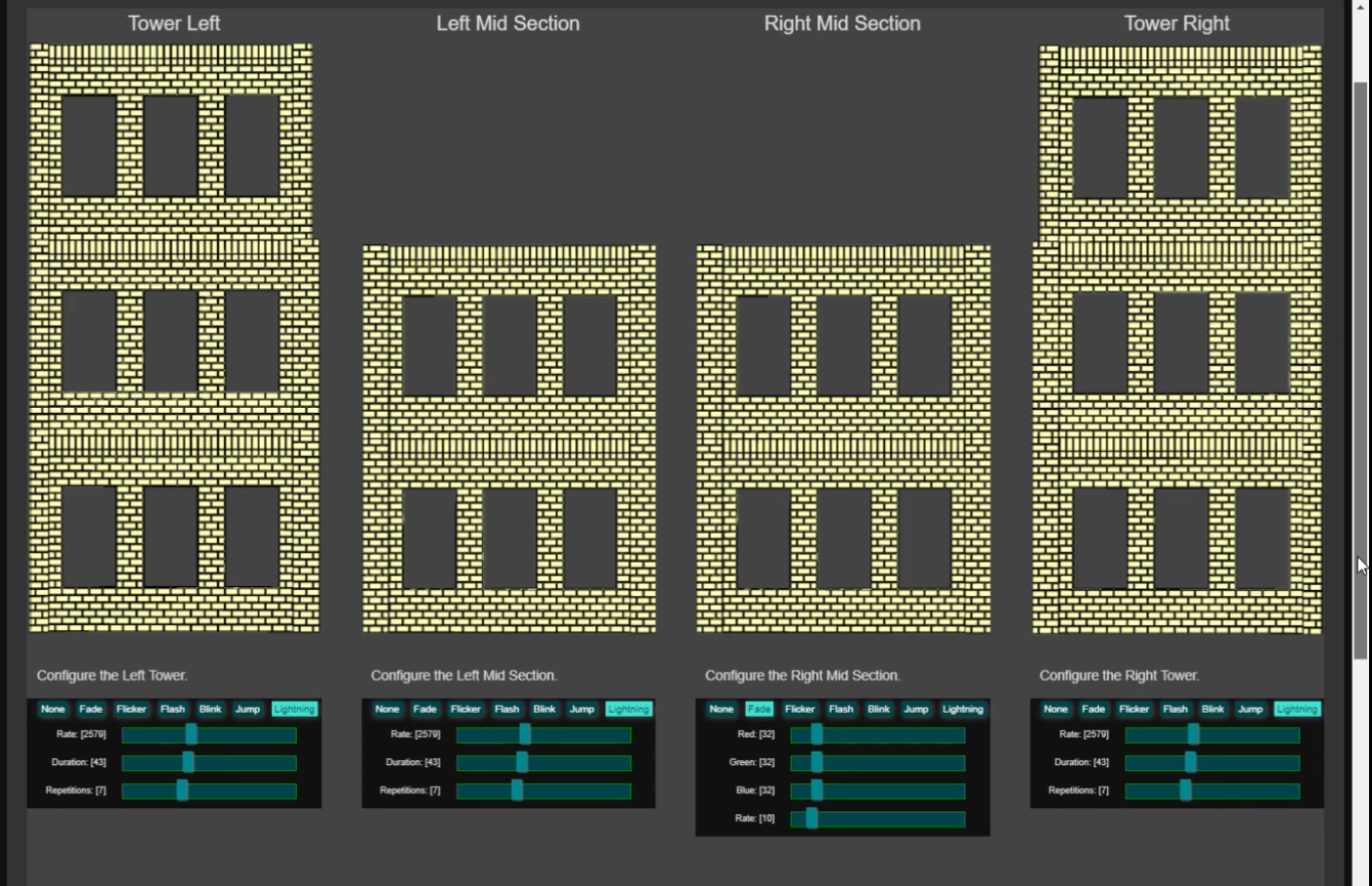

We're able to leverage the work done previously for all the Lighting controllers, with all the improvements made for the building and lithophane controllers for any

newly cast downtown buildings. The idea of adding floors and other viewblocks like interior walls needs to be addressed, not to mention routing wiring for lighting

and other features and gadgets. How to power them once the downtown streets and sidewalks and building bases are solid poured concrete needs to be addressed as well,

but that's a future installment. You can follow our Halloween Ghost Town build in more detail on our Barkyard

Blog!

See More...

We invite you to enjoy our Halloween Ghost Town on the Barkyard YouTube channel if you're so inclined. We go into much more detail than we could possibly fit on a

web page. Even our Barkyard Blog posts can't capture all the details the videos do.

View Now...